Posted By admin on December 9, 2014

We have found that even a chrome barrel and chamber have problems with sticky shells or shell residue build up, even after cleaning. When you put 400-500 rounds through your shotgun in a three-day period this can cause minor difficulties and even affect accuracy. There is now an easy way to make your chamber, forcing cone, and barrel as smooth as silk making those shells pop right out. We have even used it with Antique shotguns cleaning out rust and smoothing out pits.

We have found that even a chrome barrel and chamber have problems with sticky shells or shell residue build up, even after cleaning. When you put 400-500 rounds through your shotgun in a three-day period this can cause minor difficulties and even affect accuracy. There is now an easy way to make your chamber, forcing cone, and barrel as smooth as silk making those shells pop right out. We have even used it with Antique shotguns cleaning out rust and smoothing out pits.

This is a flexible, drill-mounted hone called the Flex-Hone® to quickly and easily produce the optimum smooth and polished surface finish in any type or size of shotgun chamber, barrel, or forcing cone.

Developed by Brush Research Manufacturing (BRM), Los Angeles, CA, the ball-style Flex-Hone Tool is characterized by small, abrasive globules permanently mounted to flexible nylon filaments. Using a flexible hone is a simple process that basically requires the means to hold a part securely such as a padded vise, the use of a low speed electric hand drill, and some common sense.

Available in a variety of lengths and grits designed to meet the various bore or gauge sizes of most types of guns, the Flex-Hone enables shotgun owners to achieve a rust-free, beautifully polished micro surface finish. As a result, many firearm manufacturers are today selecting the Flex-Hone for final finishing operations. However, the tool functions just as well in the hands of a DIYer.

Maintaining Barrels, Chambers and Force Cones

The Flex-Hone quickly, safely and thoroughly cleans out any barrel damage that has occurred from oxidation and corrosion, blend out scratches and removes the nicks and pits that cause plastic adhesion.

A flexible hone will also remove the built up residue in a barrel, and leave a superior surface resulting in greater accuracy, reduced wear and longer life for a shotgun. Standard barrel hones are 34 inches long and available in 10-, 12-, 16- and 20-gauge sizes.

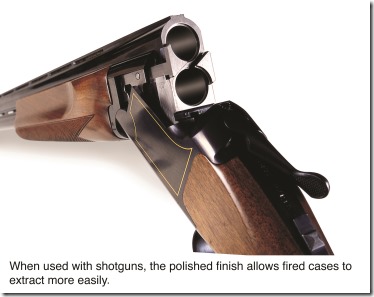

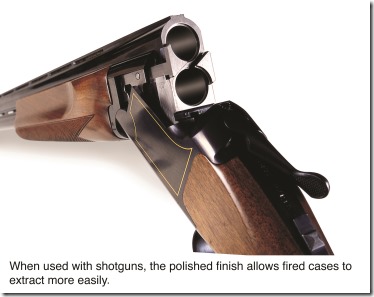

When used in shotgun chambers, the polished finish allows fired cases to extract more easily, which puts less strain on extractors and ejectors. It will also ensure that debris is far less likely to adhere to the chamber walls and any that does remain will be much easier to remove during the normal cleaning procedure.

When used in shotgun chambers, the polished finish allows fired cases to extract more easily, which puts less strain on extractors and ejectors. It will also ensure that debris is far less likely to adhere to the chamber walls and any that does remain will be much easier to remove during the normal cleaning procedure.

The forcing cone can also be polished using a flexible hone with a specially designed tapered profile Flex-Hone. Forcing cones are the first thing the shot and wadding encounter as the transition is made from chamber to barrel, the cone literally forcing the larger diameter payload down to barrel size, so it is subjected to considerable force, as its name implies.

This can lead to considerable fouling build-up close to the cone, the surface finish of which can be less smooth than either the barrel or chamber, as manufactured. Not only does the fouling create added resistance but can induce corrosion to take hold under it. Even regular cleaning may not remove it all. Honing with the Flex-Hone will ensure fouling build up is minimized.

Shotgun Owner Feedback

Johnson, who had been utilizing professional services for polishing and finishing and paying the cost plus $75 in postage, tried the Flex-Hone.

“With the Flex-Hone, I accomplished the polishing myself in half an hour,” says Johnson. “This saved me time and money. If you can operate a drill you can polish your barrels, chambers, forcing cones and cylinders yourself. I followed the instructions and had no problems at all.”

Jim O’Hanlon, a cowboy action shooter form Port St. Lucie, FL had similar results.

“Using the Flex Hone simplified the cleaning process and gave more consistent results,” says O’Hanlon. “As a cowboy action shooter, we shoot double shotguns that are not allowed to have ejectors, just extractors. Shells must fall out of the chambers with ease for fast reloads.”

Hanlon adds that he also competes in Black Powder categories, which can create what he calls “a really sticky chamber.”

“The Flex Hone gives that final, glass like smoothness that allows my extraction of empty shells to be fast,” says Hanlon.

Art Kopp, Jr. of Great Bend, PA tells of shell-hanging problems occurring with his Remington 1187 20-gauge. “The shells were not ejecting,” explains Kopp. To determine if the issue was a barrel-related malfunction Kopp switched barrels with another 20 gauge and the problem disappeared immediately.

Knowing it was a barrel issue, Kopp was able to use the Flex-Hone at home. “I used an electric drill, elbow grease, and a Flex-Hone,” says Kopp. “After, my Remington 1187 Premier Upland Special was again working flawlessly with any rounds I put through it, including cheap aluminum-hulled ones.”

Shotgun Barrel Restoration

Shotgun Barrel Restoration

Delbert Murray of Victorian Arms of Pensacola, FL describes how frustrating it can be to clean the barrels of older shotgun barrels, included double-barreled.

“We seem to have a lot of people showing up over the last two years with Grandpa’s old double barrel,” explains Murray of Victorian Arms. “Some of these were very sad cases. We did what we could for the pitted barrels [using various techniques] and it was relatively easy to knock off the surface rust and chunks of hardened powder and residue. The disappointing part was the very minute pits and scratches that remained.”

Although eager to restore the barrels to a safe condition to shoot, Murray also understood that it was extremely important that excessive material was not removed and that no area was over-worked in an attempt to remove a particularly stubborn pit or rust. Having tried a myriad of techniques, Murray learned of the Flex-Hone and decided to put it to the test.

“We were a little skeptical at first about how well it could work and chose an old Colt double 12Ga of Damascus steel to test on,” says Murray. “It could never be fired again so we couldn’t do it any harm.”

Murray was instantly impressed with the results. “The Flex-Hone was like magic. Now we use them every chance we get and the result is almost always a bright, ‘like new’ barrel in just a matter of minutes.

Victorian Arms now stocks a complete set of Flex-Hones in various sizes for all shotgun gauges, as well as for the chambers.

“It pays for itself the first time it is used on a restoration job,” says Murray.

Dennis Weinman, of Cordova AK, had a similar experience using the Flex-Hone as part of a restoration of his 1870’s vintage W.C. Scott.

“Rusty bores were a major issue,” explains Weinman. “The Flex-Hone tool removed the surface rust completely from the bores. I would have paid a professional gunsmith good money to do what I did myself. I used the flexible hone with my old drill and motor oil and got a great result.”

Weinman was also impressed that the Flex-Hone was available in the exact bore size he needed.

“The shotgun was a 10 gauge bore, so the fact that [Brush Research] had a 10 gauge Flex Hone was a restoration life saver,” says Weinman. “Moreover, it was rewarding to do the work myself and it made the result even better.”

For more information, contact Brush Research Manufacturing, Brush Research Mfg. Co., Inc., 4642 Floral Drive, Los Angeles, CA 90022; Phone: (323) 261-2193; Fax: (323) 268-6587; e-mail: info@brushresearch.com or visit the web site: www.brushresearch.com

For a simple Flex-Hone for Firearms Instructional Video go to our YouTube page. http://www.youtube.com/BrushResearch

Category: Guns & Acc., Shotgun Sports |

No Comments »

Tags: cleaning firearms, cleaning shotguns, competitive shooting, honing, honing systems, jr shooter, jr shooters, junior, junior camps, junior shooter, junior shooters, junior shooting camps, junior writers, juniors, kids, learn to shoot, learning to shoot, Olympics, plinking, shooting, shooting sports, shotguns, usa shooting, youth shooting, youth shooting sports

I hope you all have a very happy and rewarding new year. Lots of fun, some great shooting and time with family. Always keep in mind that safety comes first whenever you are around firearms whether it is at the range or at home.

I hope you all have a very happy and rewarding new year. Lots of fun, some great shooting and time with family. Always keep in mind that safety comes first whenever you are around firearms whether it is at the range or at home.

FORT SMITH, AR (November 17th, 2014)— Are you the best shot you can be with your air rifle? Tune in for this week’s Round Table where Rossi Morreale, Jim Chapman, Tom Gaylord, and Rick Eutsler provide expert tips that help you improve your shooting skills.

FORT SMITH, AR (November 17th, 2014)— Are you the best shot you can be with your air rifle? Tune in for this week’s Round Table where Rossi Morreale, Jim Chapman, Tom Gaylord, and Rick Eutsler provide expert tips that help you improve your shooting skills.

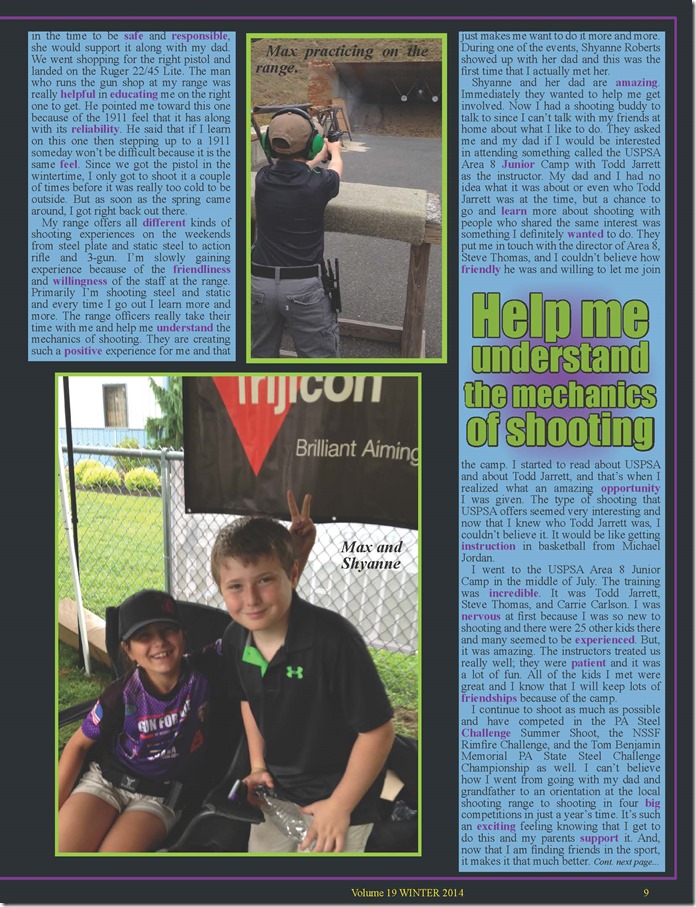

I recently got a chance to test a Browning Buck Mark. It is a very cool gun and really nice to shoot. It has a match trigger that is very short and crisp. It has a chrome barrel and wooden grips. The green bead of the front sight makes the sight picture very clear when looking through it. When I shoot it, I do very well with it, and it has become my favorite gun.

I recently got a chance to test a Browning Buck Mark. It is a very cool gun and really nice to shoot. It has a match trigger that is very short and crisp. It has a chrome barrel and wooden grips. The green bead of the front sight makes the sight picture very clear when looking through it. When I shoot it, I do very well with it, and it has become my favorite gun.

http://www.Facebook.com/AmericanAirgunner

http://www.Facebook.com/AmericanAirgunner

For over a decade, the CMP Junior Air Rifle Camps have been a popular destination for junior marksmen during the summer. High-school age (9-12 grade) athletes learn intermediate and advanced air rifle marksmanship skills through various exercises and demonstrations. Throughout the course of the camp, juniors learn tips for both the physical and mental aspects of competition shooting, including positioning, goal setting and proper use of equipment.

For over a decade, the CMP Junior Air Rifle Camps have been a popular destination for junior marksmen during the summer. High-school age (9-12 grade) athletes learn intermediate and advanced air rifle marksmanship skills through various exercises and demonstrations. Throughout the course of the camp, juniors learn tips for both the physical and mental aspects of competition shooting, including positioning, goal setting and proper use of equipment.  The Civilian Marksmanship Program’s newly added Monthly Match League has now completed its fourth month, allowing some of its leading competitors to surface. Monthly Matches were held at the South CMP Marksmanship Center in Anniston, AL, as well as the Gary Anderson CMP Marksmanship Center at Camp Perry, OH, in March, April, May and September. Competitors must fire in four or more matches to be eligible for league prizes. The final two Monthly Matches are scheduled for October 18 and November 15.

The Civilian Marksmanship Program’s newly added Monthly Match League has now completed its fourth month, allowing some of its leading competitors to surface. Monthly Matches were held at the South CMP Marksmanship Center in Anniston, AL, as well as the Gary Anderson CMP Marksmanship Center at Camp Perry, OH, in March, April, May and September. Competitors must fire in four or more matches to be eligible for league prizes. The final two Monthly Matches are scheduled for October 18 and November 15.  ANNISTON, AL – The Civilian Marksmanship Program is mourning the passing of a friend and legal counsel, Michael Saporito, 76, of Winter Springs, Florida. Mr. Saporito passed away on September 3, 2014 after a brief illness. “We are deeply saddened by the loss of our attorney and colleague. Mike knew the firearms safety business, understood and believed in the mission of the corporation, and was an exceedingly proficient lawyer. He was a true friend, supporter, and mentor to the CMP. His knowledge of the law, tempered by his unique wit and humor, cannot be replaced. We will indeed miss him,” said Judy Legerski, Chairman, CMP Board of Directors.

ANNISTON, AL – The Civilian Marksmanship Program is mourning the passing of a friend and legal counsel, Michael Saporito, 76, of Winter Springs, Florida. Mr. Saporito passed away on September 3, 2014 after a brief illness. “We are deeply saddened by the loss of our attorney and colleague. Mike knew the firearms safety business, understood and believed in the mission of the corporation, and was an exceedingly proficient lawyer. He was a true friend, supporter, and mentor to the CMP. His knowledge of the law, tempered by his unique wit and humor, cannot be replaced. We will indeed miss him,” said Judy Legerski, Chairman, CMP Board of Directors.  For a group of juniors from Virginia, a routine outing left them thinking outside of the box, or rather, outside of the air range. With open minds and a fearless leader, they stepped outside and into the unknown – the domain of highpower.

For a group of juniors from Virginia, a routine outing left them thinking outside of the box, or rather, outside of the air range. With open minds and a fearless leader, they stepped outside and into the unknown – the domain of highpower.

CMP’s State Directors provide leadership, resource and program information, coordination, networking, motivation and publicity for junior shooting within their state. The State Director featured is Joseph Matter, of Vashon, WA.

CMP’s State Directors provide leadership, resource and program information, coordination, networking, motivation and publicity for junior shooting within their state. The State Director featured is Joseph Matter, of Vashon, WA.

Garand-Springfield-Military Rifle Master Instructor Clinics – 10-11 October, Phoenix, AZ – Experienced rifle marksmanship instructors and shooters who would like to receive advanced training and be certified as “Master Instructors” to teach CMP-sanctioned Garand, Springfield and Vintage Military Rifle or Rimfire Sporter Clinics are invited to apply to attend a CMP Master Instructor Training Workshop.

Garand-Springfield-Military Rifle Master Instructor Clinics – 10-11 October, Phoenix, AZ – Experienced rifle marksmanship instructors and shooters who would like to receive advanced training and be certified as “Master Instructors” to teach CMP-sanctioned Garand, Springfield and Vintage Military Rifle or Rimfire Sporter Clinics are invited to apply to attend a CMP Master Instructor Training Workshop.

CMP Monthly Matches, CMP Marksmanship Centers –

CMP Monthly Matches, CMP Marksmanship Centers –